- Product display

- CNC CORNER FORMING MACHINE

- Lateral Punching Machine

- ALUMINUM PLATE SHARP CORNER FORMING MACHINE

- Laser Welding Platform

- CNC HYDRAULIC LOWER TRANSMISSION BENDING MACHINE

- CNC BUSBAR PROCESSING MACHINE

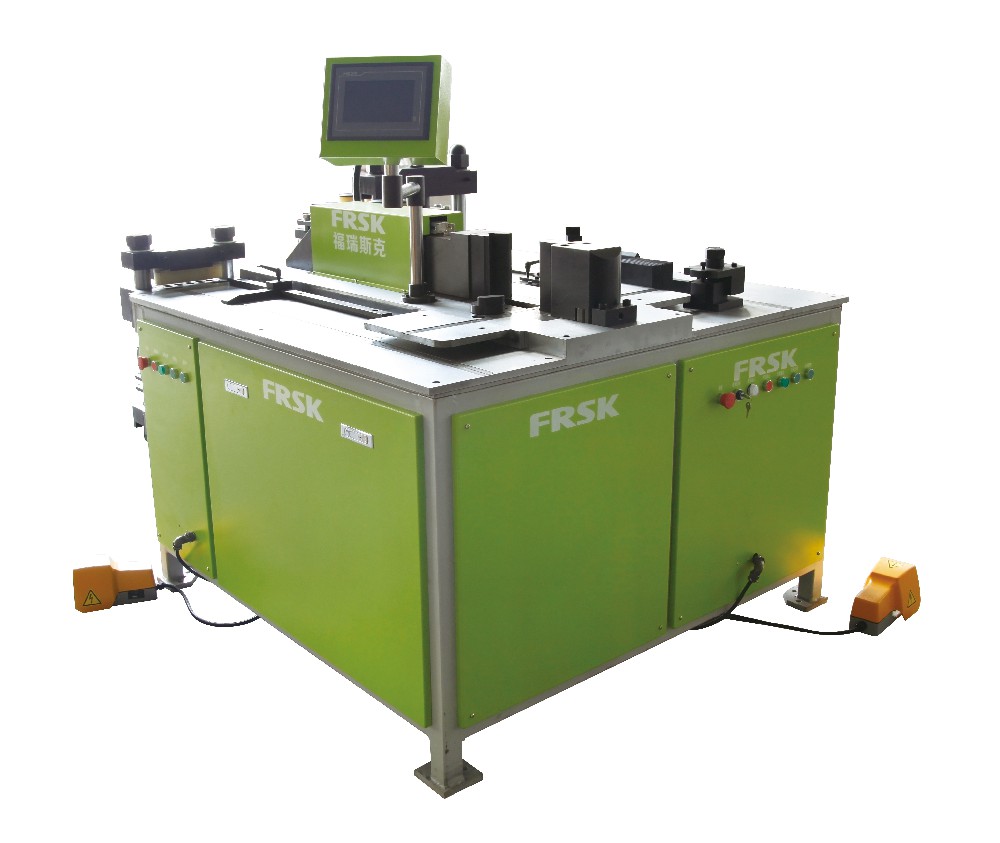

4+2 Superposition-style Turret Busbar Processing Machine

Application Area

4+2 Superposition-style Turret Busbar Processing Machine

Technical Features

1.The punching unit structure (4+2) is the best combination of four single-hole and two four- hole, large and small turntables are superposition-style and interactive,six sets of dies can be shared ,no need to be changed .When single hole needs to be punched, just manually change the angle of the single hole die, draw the punching position line of the copper bar, and then punch after fix a position with the electric light, which is convenient and fast.

2.Advantage of four-hole punching is to maximize work efficiency and reduce the labor intensity of workers ,When punching, the copper/aluminum bar does not need to move horizontally. The high-quality die base structure ensures the accuracy of punching, greatly reduces the loss of the die, and realizes the latest breakthrough in punching processing.

3.The front supporting material and the back pressing material shear at same time ,shearing workpiece double section is vertical ,no waste material .

4.copper/aluminum bar bending process is controlled by PLC and grating ruler,angle can be controlled and easy to choose ,high accurancy and efficiency .

Model/Specificaiton | 903DZTSK | 903DZTSK-2 | 903DZTSK-3 | 903DZTSK2 | 903DZTSK2-2 | 903DZTSK2-3 | |

Number of punching mode | Single hole punches four mode ,four holes punch two mode | ||||||

Punching process | Max.punching force(KN) | 900 | 900 | 900 | 900 | 900 | 900 |

Punching range(mm) | φ4.3~φ25 | φ4.3~φ25 | φ4.3~φ25 | φ9~φ21 | φ9~φ21 | φ9~φ21 | |

Max.processing thickness(mm) | 16 | 16 | 16 | 12 | 12 | 12 | |

Max.processing width(mm) | 160 | 160 | 160 | 120 | 120 | 120 | |

Shearing process | Max.shearing force (KN) | 500 | 500 | 500 | 500 | 500 | 500 |

Max.shearing thickness(mm) | 16 | 16 | 16 | 16 | 16 | 16 | |

Max.shearing width(mm) | 160 | 160 | 160 | 160 | 160 | 160 | |

Bending process | Max.bending force(KN) | 300 | 300 | 300 | 300 | 300 | 300 |

Max.bending thickness(mm) | 16 | 16 | 16 | 16 | 16 | 16 | |

Max.bending width(mm) | 160 | 160 | 160 | 160 | 160 | 160 | |

Vertical bending process | Bending width(mm) | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 |

U-sharped bending process | Bending range (mm) | >80 | >80 | >80 | >80 | >80 | >80 |

Worktable size(mm) | 1400×1400×900 | ||||||

Main motor power(KW) | 5.5 | 5.5+4 | 5.5+2×4 | 5.5+2×4 | 5.5+2×4 | 5.5+2×4 | |

Weight(T) | 1.4 | 1.5 | 1.6 | 1.4 | 1.5 | 1.6 | |

Instruction | Stations are used interchangeably | Two stations work at the same time | Three stations work at the same time | Stations are used interchangeably | Two stations work at the same time | Three stations work at the same time | |

Random accessory | Punching die: 8 sets | φ7、φ9、φ11、φ13、φ17、φ21、φ11×15、φ13×17 | |||||

Shearing die: 1set | 160 | ||||||

Bending die:4 sets | Large flat bending, small flat bending、Super vertical bending 、U-sharped bending | ||||||

Embossing die | 130×40 | ||||||

Customized die | Common four-hole die | φ17×60、φ13×50、φ11×40、φ9×30(others can be made as the request ) | |||||

303 Turret Type CNC Busbar Processing Machine

Application Area

This machine is mainly used to process various specificaitions of copper .aluminum busbars, Users can punch / shear / fold the busbars as long as they choose the corresponding processing unit,high efficiency ,it is the ideal machine for high and low pressure electric appliance manufacturing industry .

Technical Features

Plum blossom turret eight mode ,turret part is made of ductile iron(service life of single hole improves 3 times ,whole service life improves more than 20 times ),long holes.round holes can be arbitrary mixed ;large tonnage oil cylinder is used for shearing , shearing workpiece double section is vertical; the standby pressure of oil pump decreases,service life improve several times .

Model/Specificaiton | 303ZT | 303ZT-2 | 303ZT-3 | 303ZT | 303ZT-2 | 303ZT-3 | |

303ZTSK | 303ZTSK-2 | 303ZTSK-3 | 303ZTSK | 303ZTSK-2 | 303ZTSK-3 | ||

Number of punching mode | Punch eight mode | ||||||

Punching process | Max.punching force(KN) | 300 | 300 | 300 | 300 | 300 | 300 |

Punching range(mm) | φ4.3~φ25 | φ4.3~φ25 | φ4.3~φ25 | φ4.3~φ25 | φ4.3~φ25 | φ4.3~φ25 | |

Max.processing thickness(mm) | 16 | 16 | 16 | 16 | 16 | 16 | |

Max.processing width(mm) | 160 | 160 | 160 | 160 | 160 | 160 | |

Shearing process | Max.shearing force (KN) | 500 | 500 | 500 | 500 | 500 | 500 |

Max.shearing thickness(mm) | 16 | 16 | 16 | 16 | 16 | 16 | |

Max.shearing width(mm) | 160 | 160 | 160 | 160 | 160 | 160 | |

Bending process | Max.bending force(KN) | 300 | 300 | 300 | 300 | 300 | 300 |

Max.bending width(mm) | 160 | 160 | 160 | 160 | 160 | 160 | |

Max.bending thickness(mm) | 16 | 16 | 16 | 16 | 16 | 16 | |

Vertical bending process | Bending width(mm) | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 | 30~120 |

U-sharped bending process | Bending range(mm) | >80 | >80 | >80 | >80 | >80 | >80 |

Worktable size(mm) | 1400×1200×900 | ||||||

Main motor power(KW) | 4 | 2×4 | 3×4 | 4 | 2×4 | 3×4 | |

Weight(T) | 1.2 | 1.3 | 1.45 | 1.2 | 1.3 | 1.45 | |

Instruction | Stations are used interchangeably | Two stations work at the same time | Three stations work at the same time | Stations are used interchangeably | Two stations work at the same time | Three stations work at the same time | |

Random accessory | Punching die :8 sets | φ7、φ9、φ11、φ13、φ17、φ21、φ11×15、φ13×17 | |||||

Shearing die :1 set | 160 | ||||||

Bending die :4 sets | Large flat bending, small flat bending、Super vertical bending 、U-sharped bending 1 set each , Embossing die(130*40) | ||||||